The automotive industry has seen significant advancements in technology and manufacturing practices, particularly in the production of critical components like the Land Rover fuel pump. According to a report by the International Organization of Motor Vehicle Manufacturers (OICA), the global automotive parts market is projected to grow significantly, with a focus on quality and efficiency driving demand for high-performance components.

In this context, the importance of reliable fuel pumps cannot be understated—approximately 20% of vehicle recalls are attributed to fuel system failures, underscoring the need for superior manufacturing standards. As China's manufacturing capabilities continue to expand and innovate, exceptional Land Rover fuel pumps crafted in this region are setting new benchmarks for global excellence, combining cutting-edge technology with rigorous quality controls to meet the diverse needs of the automotive market.

The manufacturing of Land Rover fuel pumps in China adheres to exceptional standards, setting a benchmark for quality and reliability in the automotive industry. According to a recent report by MarketsandMarkets, the global automotive fuel pump market is projected to reach $16.5 billion by 2026, with an increasing demand for high-performance components. This growth is driven by the escalation of electric vehicle (EV) production and the ongoing enhancements in fuel injection technologies, highlighting the critical role of fuel pumps in achieving engine efficiency and reduced emissions.

China, as a manufacturing powerhouse, leverages advanced technologies and stringent quality control processes to produce fuel pumps that not only meet but exceed international standards. The ISO 9001 certification process ensures that manufacturers maintain consistent quality, which is crucial for Land Rover’s reputation for luxury and performance. Furthermore, a comparison study by Frost & Sullivan found that components manufactured in China can often achieve up to 30% lower defect rates than those produced in other regions, proving that excellence in manufacturing is attainable on a global scale. This pursuit of quality not only supports the supply chains of renowned brands like Land Rover but also strengthens China's position in the high-stakes automotive sector.

In the realm of automotive engineering, fuel pumps play a pivotal role in ensuring optimal vehicle performance. Recent advancements in design and technology have positioned Chinese manufacturers at the forefront of producing exceptional Land Rover fuel pumps, contributing to global automotive excellence. According to a report by MarketsandMarkets, the global fuel pump market is projected to grow from USD 16.5 billion in 2021 to USD 24.4 billion by 2026, highlighting the increasing demand for efficient and reliable fuel delivery systems.

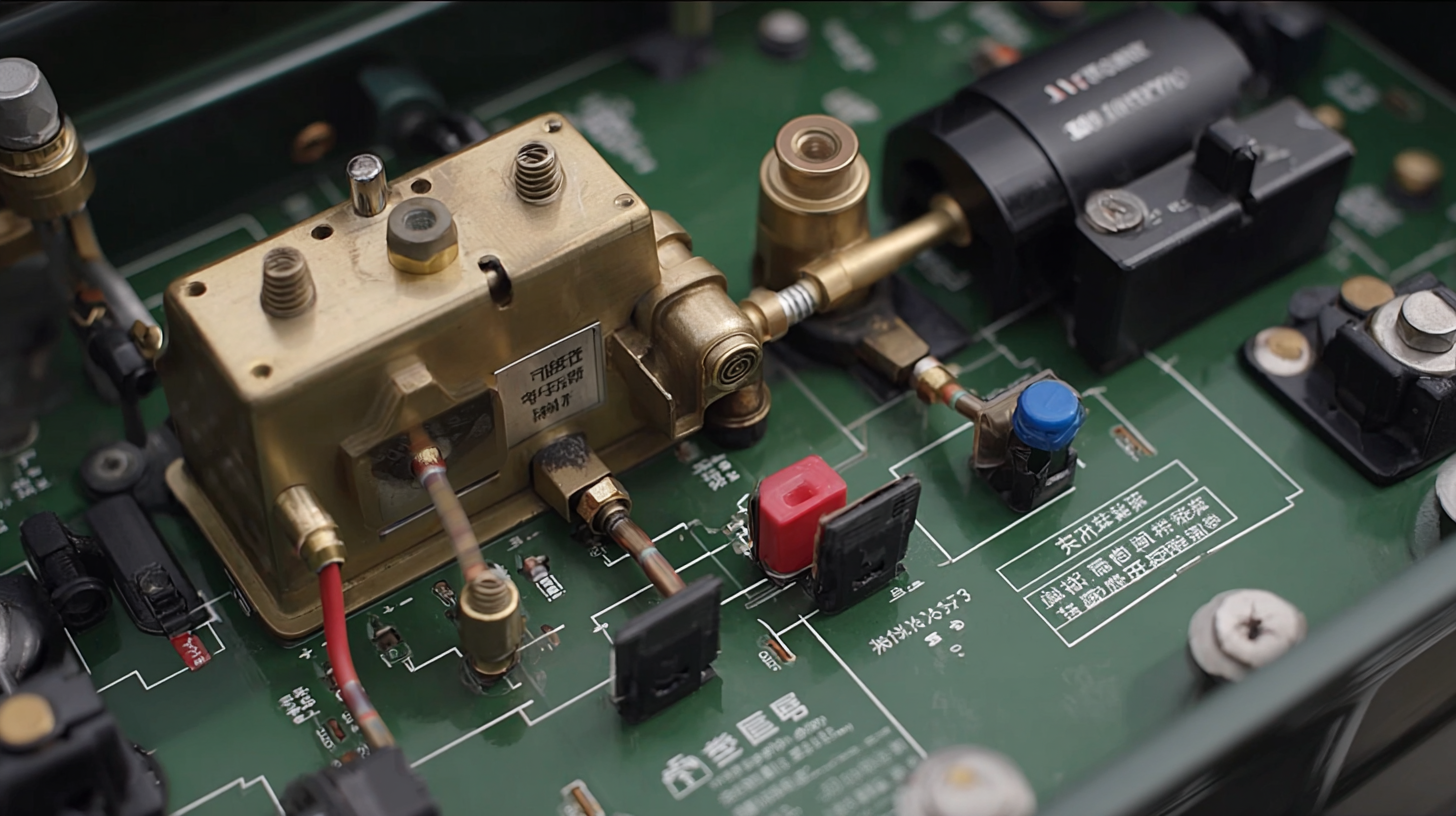

Key components such as diaphragm membranes, impellers, and electronic control units are integral to the innovation in fuel pump design. Recent developments in materials science have led to the use of advanced polymers, which offer greater resistance to temperature and chemical degradation, thereby enhancing durability and performance. Additionally, the integration of smart technology, including real-time monitoring systems, allows for improved efficiency and responsiveness in fuel delivery—critical features for high-performance vehicles like Land Rovers. With China's commitment to quality manufacturing and technological advancement, the production of fuel pumps is not only about meeting standards but also about pushing the boundaries of performance and sustainability in the automotive sector.

China has emerged as a pivotal player in the realm of global fuel pump innovation, particularly in the automotive sector. The nation’s ability to combine traditional manufacturing techniques with cutting-edge technology has led to the production of exceptional fuel pumps, specifically designed for high-performance vehicles like Land Rovers. With significant investments in research and development, Chinese manufacturers are not only meeting local demands but are also setting standards for international markets.

This innovation stems from a robust industrial ecosystem that thrives on collaboration between various sectors, including engineering, technology, and materials science. By leveraging this synergy, Chinese companies have developed fuel pumps that offer enhanced efficiency, reliability, and sustainability, catering to the evolving needs of environmentally conscious consumers worldwide. As a result, the reputation of Chinese-made fuel pumps continues to grow, reinforcing the country’s role as a leader in automotive component production and contributing significantly to global market dynamics.

| Fuel Pump Type | Material | Flow Rate (L/min) | Pressure Range (Bar) | Applications |

|---|---|---|---|---|

| Electric Fuel Pump | Aluminum Alloy | 50 | 3-5 | Passenger Vehicles |

| High-Pressure Fuel Pump | Stainless Steel | 100 | 6-10 | Performance Vehicles |

| In-Tank Fuel Pump | Plastic Composite | 40 | 2-4 | Compact Cars |

| Mechanical Fuel Pump | Cast Iron | 30 | 1.5-3 | Vintage Vehicles |

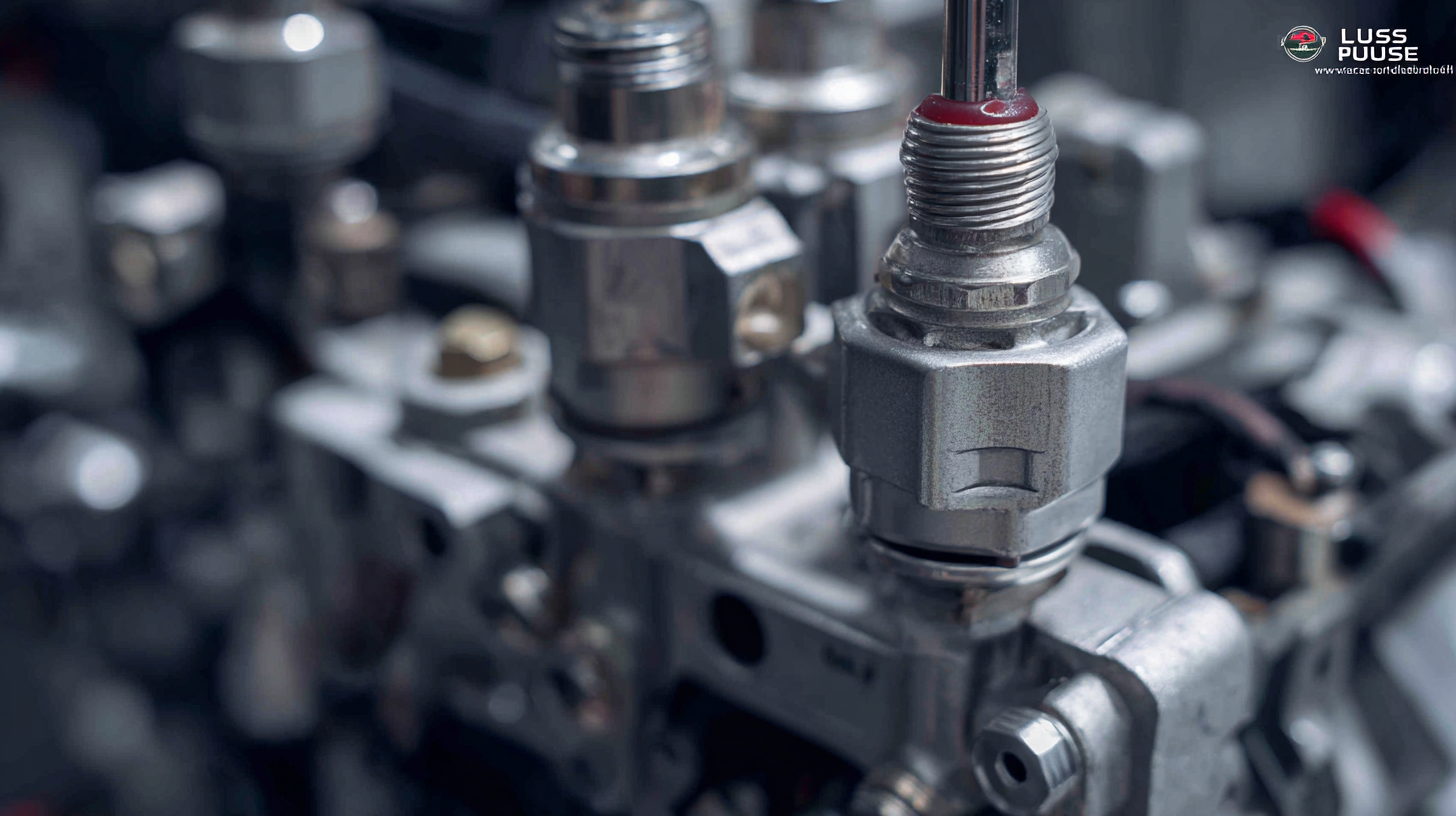

In the competitive world of automotive components, quality control is essential, especially for critical parts such as fuel pumps. The production of Land Rover fuel pumps in China has become synonymous with meticulous quality measures that guarantee performance and durability. Manufacturers implement rigorous testing protocols at every stage of production, ensuring that each pump meets stringent specifications. From the initial material selection to final assembly, thorough inspections and testing are conducted to maintain high standards.

Automated technology plays a crucial role in the quality control process. Advanced machinery is employed for precision manufacturing, minimizing human error and enhancing consistency across batches. Furthermore, skilled technicians closely monitor production lines, utilizing real-time data analytics to detect and address potential issues before they escalate. This proactive approach not only safeguards the integrity of the fuel pumps but also reinforces the commitment to excellence that has made Chinese manufacturing a respected name in the global market.

As the automotive industry navigates a transformative era, the focus on fuel pump technology has become increasingly vital amidst rising environmental concerns. According to a recent report by MarketsandMarkets, the global fuel pump market is projected to reach $42 billion by 2025, growing at a CAGR of 7.5%. This growth is driven by the demand for more efficient fuel systems in both traditional combustion engines and electric vehicles (EVs). Innovations like smart fuel pumps equipped with IoT capabilities are on the rise, allowing real-time monitoring and maintenance, which can reduce the environmental footprint of fossil fuel consumption.

Tip: When choosing a fuel pump for your Land Rover, consider models that utilize advanced materials and designs to enhance fuel efficiency and reduce emissions. Look for pumps that comply with the latest industry standards, as these are often optimized for reduced leakage and improved performance.

The environmental impact of fuel pump technology extends beyond the mechanics of the pump itself. By integrating cleaner production methods and recyclable materials in the manufacturing process, companies can significantly decrease their carbon footprint. A study by McKinsey indicates that companies that implement sustainable practices can see a 20-30% reduction in costs over time—an attractive proposition for a sector that is increasingly under pressure to adopt greener solutions.

Tip: Stay informed about the latest advancements in fuel pump technology, as new solutions are constantly emerging that can offer both performance benefits and environmental advantages.